- 19 newly developed brake components in four years of development work

- New plant with 6,000 square meters of floor space and complete vertical integration

- Series production to start in 2026, including on the KTM 390 Duke

After decades as an established chassis supplier, WP is taking a strategically important step. With the founding of WP Braking Systems, the company is expanding its portfolio to include complete braking systems for the first time. This brings into focus an area that has previously been strongly dominated by external suppliers.

From suspension specialist to brake brand

The roots of WP Suspension date back to the 1970s. Coming from motocross, the company developed into KTM’s regular suspension supplier in the 1980s. WP was completely taken over in the 1990s, and since 2009 the company has been based in Austria, in the immediate vicinity of the motorcycle manufacturer.

Following the change of ownership at KTM, WP made a comeback in mid-January 2026 with a far-reaching announcement. In addition to shock absorbers and upside-down telescopic forks, WP Braking Systems is being established as an independent brake division. The new brand will offer high-performance brake solutions for series production, racetracks, and accessories.

Development and production in-house

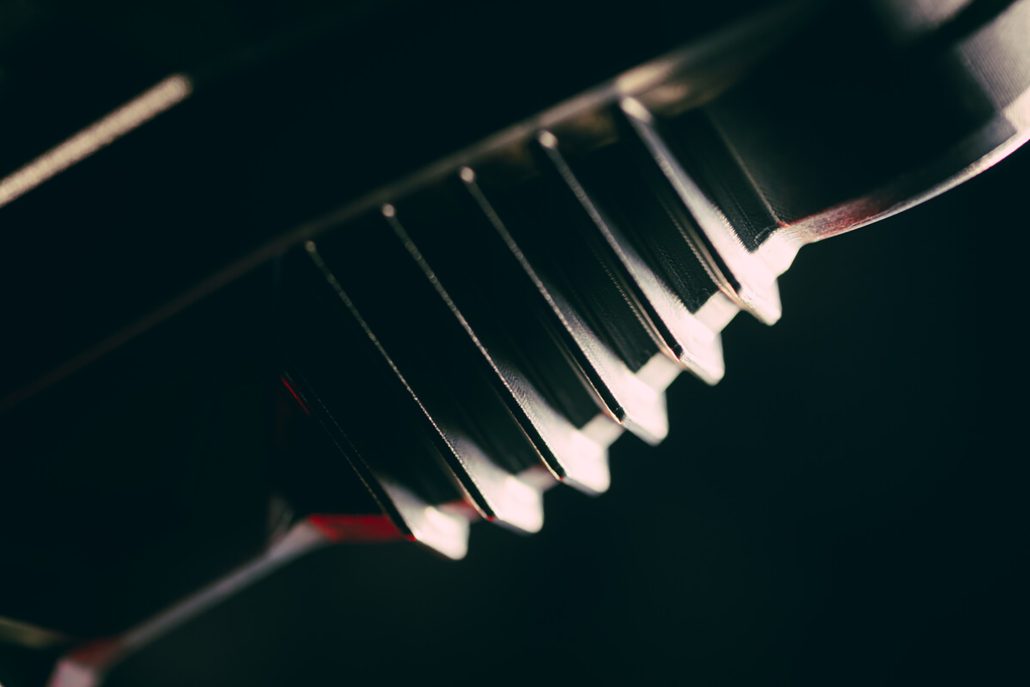

At the heart of the new brake strategy is a completely internal development process. According to WP, a total of 19 brake components have been redesigned over a period of four years. The spectrum ranges from simple single-piston calipers to milled monoblock four-piston radial brakes.

According to the company, the development team consists of eleven specialists, each with more than 20 years of experience in brake development. They work in a 6,000-square-meter SOP-ready factory with modern test benches and prototyping facilities. Their tasks range from advanced engineering and CAD design to complete validation processes.

A key element is complete vertical integration. From braiding the brake lines to extrusion and mechanical processing to final assembly, every step takes place in-house. The production is complemented by a 100-meter-long anodizing plant for surfaces and finishes. The maximum capacity is up to 300,000 brake systems and around 1.5 million brake lines per year.

Focus on weight, cooling, and maintenance

According to WP, the focus in developing the new brakes was on weight reduction and heat management. The aim was to ensure consistent braking performance even under high continuous loads. At the same time, the technology is to be transferred to smaller displacement classes of powerful motorcycles.

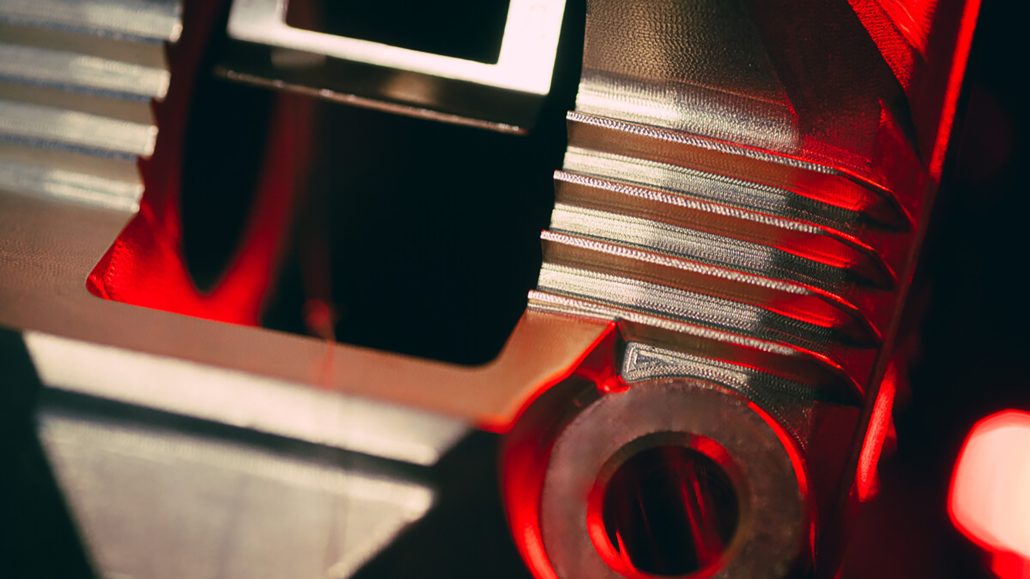

One example of this is the newly developed front radial brake caliper with four pistons. With a stated weight of 740 grams, it is one of the lightest of its kind, according to the manufacturer. A central web structure is designed to provide high rigidity in a compact design. The reduced width makes the caliper compatible with spoked wheels.

Other technical features include a die-cast aluminum housing, hard-anodized aluminum pistons, EPDM quad rings and dust seals, and the option of using sintered or organic brake pads. In addition, rear floating calipers with an open bridge cooling concept and oversized pads are used. The design is geared towards simplified maintenance.

Steel-braided brake lines as standard

All brake systems from WP Braking Systems are supplied with steel-braided brake lines as standard. These are made of polytetrafluoroethylene and are designed to withstand pressures of up to 40 bar. This is intended to enable a more direct and defined braking feel as well as consistent response.

In addition, according to WP, drag torque has been specifically reduced. This is intended to improve the overall performance of the motorcycle while reducing brake pad wear and fuel consumption.

First series production use from 2026

The new components will see their first series production use in the 2026 model year KTM 390 Duke. The front will feature the radially mounted WP FCR4 four-piston brake caliper, while the rear will feature a WP RCF4 single-piston brake caliper. This replaces the previous supplier Bybre, a subsidiary of Brembo.

Further models from KTM, Husqvarna, and GasGas are to follow. At the same time, WP Braking Systems plans to position itself as an OEM supplier for other manufacturers. In addition, a later accessories business for end customers is planned.

Classification and outlook

With WP Braking Systems, WP is significantly expanding its role as a component manufacturer. It remains to be seen whether the new brand will become a serious alternative to established brake manufacturers in the long term. However, the technical depth, in-house production, and early series production suggest that WP does not view this step as a short-term project.

What does this mean for me as a motorcyclist?

For motorcyclists, the introduction of WP Braking Systems means, above all, greater integration of brake technology into the overall design of the motorcycle. In the future, brakes, chassis, and vehicle tuning will more often come from a single source and be better coordinated with each other. In practice, this can mean more consistent response, constant performance under high loads, and simplified spare parts supply. At the same time, it can be assumed that the new brakes will first have to prove themselves in large-series models before they can establish themselves on the market in the long term. For customers, this means that it is not so much the basic principle of braking that is changing, but rather the origin and development philosophy of the components used.

- MICHELIN 091745Michelin – Pilot Power 2ct Rear – 190/50 Zr17 Tl 73(w) Rear – Sommerreifen