- Base vehicle: Honda CBR300R

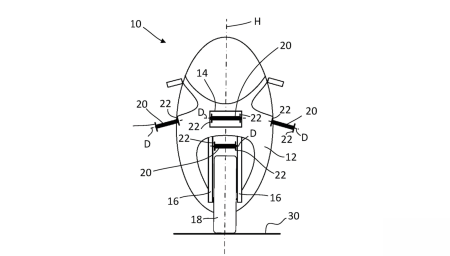

- Concept: split rear wheel with two half wheels

- Development stages: Split Wheel Version 1 and Version 2

What began as a joke idea developed within a few months into one of the most unusual motorcycle projects of recent years. The team at Bikes and Beards wanted to find out whether the principle of a split wheel, familiar from an experiment with bicycles, could also be applied to a motorized two-wheeler. The answer turned out to be much more complex than expected.

The basic idea behind the split wheel

The central concept is easy to explain: the classic rear wheel is split in half and mounted side by side. Both half wheels are designed to have alternating ground contact. In theory, this results in continuous power transmission, even though the contact surface is constantly changing.

In practice, however, this principle means that the wheelbase, contact patch, and load distribution are constantly changing. This is precisely where the biggest challenges of the project lay.

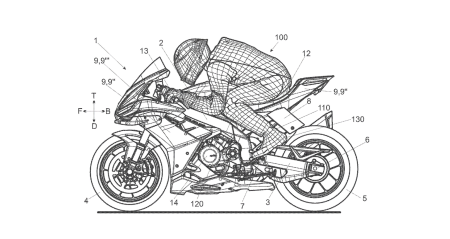

Split Wheel Version 1: The first drivable prototype

The team deliberately chose a Honda CBR300R for the first version. One of the decisive factors was the steel swing arm, which was relatively easy to extend and modify. In addition, a second rear wheel was integrated, which was driven by an additional sprocket.

The first uncertainties became apparent during construction. The two tires used were not identical, differing in tread and wear. The team also experimented with improvised filling materials such as spray foam and rubber mulch to keep the halved tires dimensionally stable.

The motorcycle was basically ready to ride, but revealed massive problems:

- strong vibrations even at low speeds

- unsteady up and down movement of the rear end

- changing wheelbase while riding

The riding experience was more reminiscent of a vibrating tool than a motorcycle. Comfort was practically non-existent. Nevertheless, the motorcycle could be moved, which showed the creators that the basic concept had not completely failed.

Root cause analysis according to version 1

After the first test drives, it became clear that several factors were simultaneously responsible for the problems. One of the most important issues was the lack of ground contact of the two half wheels. At certain moments, neither of the two wheels made proper contact with the asphalt.

Added to this was the working rear suspension. With each suspension movement, the angle of the swing arm changed. This also changed the distance between the half wheels and the road. The result was uncontrollable rocking.

The drive also proved to be critical. Two driven half wheels require an absolutely identical gear ratio. Even minimal deviations led to tension and additional instability.

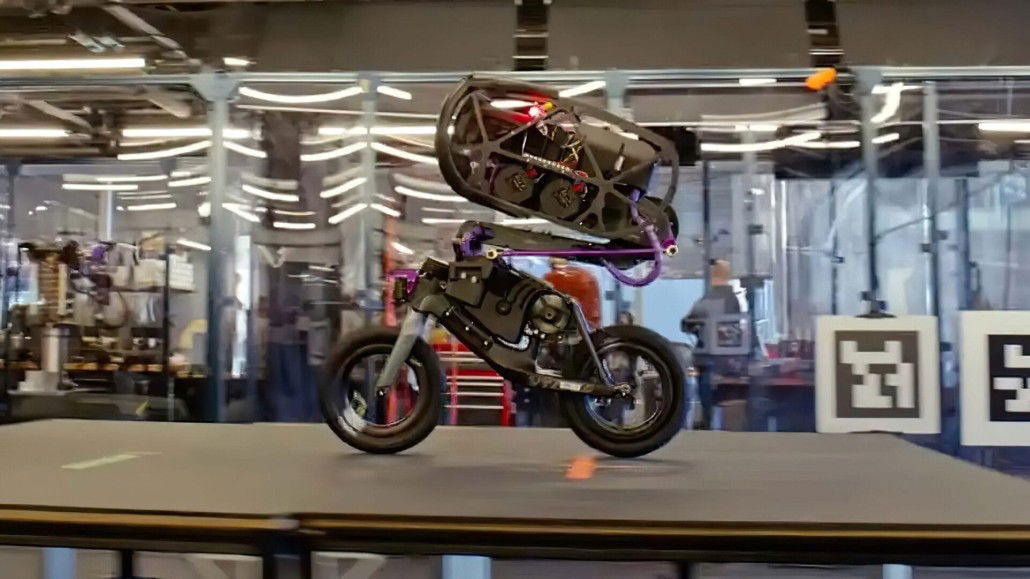

Split Wheel Version 2: Technical restart

For version 2, the team decided to extensively rebuild the rear. The goal was to eliminate as many variables as possible and make the system reproducible.

The most important changes included:

- Use of two identical new tires

- Precise cutting of both half wheels to the same height

- Use of mousse inserts instead of liquid or loose filling materials

- Revision of the drive and sprocket synchronization

A decisive step was the temporary abandonment of classic rear suspension. Instead of a shock absorber, a rigid metal strut was installed. This kept the swing angle constant, regardless of unevenness.

Fine-tuning and new problems

Although the handling improved significantly, the system remained extremely sensitive. During testing, it became apparent that even swapped chainwheel drivers were enough to throw the two half-wheels out of sync. In this state, they rotated at different speeds, which was classified as potentially dangerous.

After correcting this error, further calibration runs followed. Only then did the team feel ready for the decisive step.

The highway test with version 2

The declared milestone of the project was reaching highway speed. After several preliminary tests, the road finally led to the expressway. Compared to version 1, the motorcycle seemed much smoother. The vibrations were still present, but no longer uncontrollable.

It was interesting to observe that the handling stabilized to some extent as the speed increased. From about 35 mph, or around 56 km/h, the system seemed to reach a smoother range. Shortly thereafter, however, a new defect occurred. One of the mousse inserts began to work its way out of the half wheel. The test was then terminated.

Conclusion: Findings from two versions

The Split Wheel project impressively demonstrates how big the difference is between a theoretically functioning idea and its practical implementation. Version 1 made it clear that the concept is fundamentally rideable, but has massive disadvantages. Version 2 proved that many of these problems can be reduced technically, but only with considerable effort.

The key findings from both development stages:

- Perfect symmetry is essential.

- The slightest deviations lead to strong vibrations.

- Comfort and riding stability remain critical.

- The technical effort involved is disproportionate to the benefits.

This project makes it clear why split wheels have not yet become established in motorcycle construction. Nevertheless, Split Wheel 1 and 2 provide valuable insights into driving dynamics, drive synchronization, and the limits of unconventional concepts.

Whether a third version will follow remains to be seen. However, the project has already shown how far even absurd ideas can be taken with sufficient time and a willingness to experiment.

What does this mean for me as a motorcyclist?

From a motorcyclist’s point of view, the Split Wheel project shows one thing above all: unconventional technical ideas can be implemented, but often bring more disadvantages than benefits in real-world riding. The tests clearly show how sensitively a motorcycle’s chassis, tires, and drive react to even the smallest deviations. Even minimal differences in tire height, weight, or gear ratio lead to noticeable vibrations and unstable handling. For everyday use, this means that proven concepts have become established for good reason. A well-tuned chassis, suitable tires, and a functioning suspension are crucial for stability, comfort, and safety. The Split Wheel Project is therefore less a blueprint for future motorcycles and more an illustrative experiment that highlights how complex motorcycle technology actually is.

- Milestone MotoGP 25 Day 1 Edition (PS5)