- Patent describes a swing arm with integrated hydraulic unit and additional joint

- Adjustment of rear wheel position depending on acceleration, deceleration, and cornering

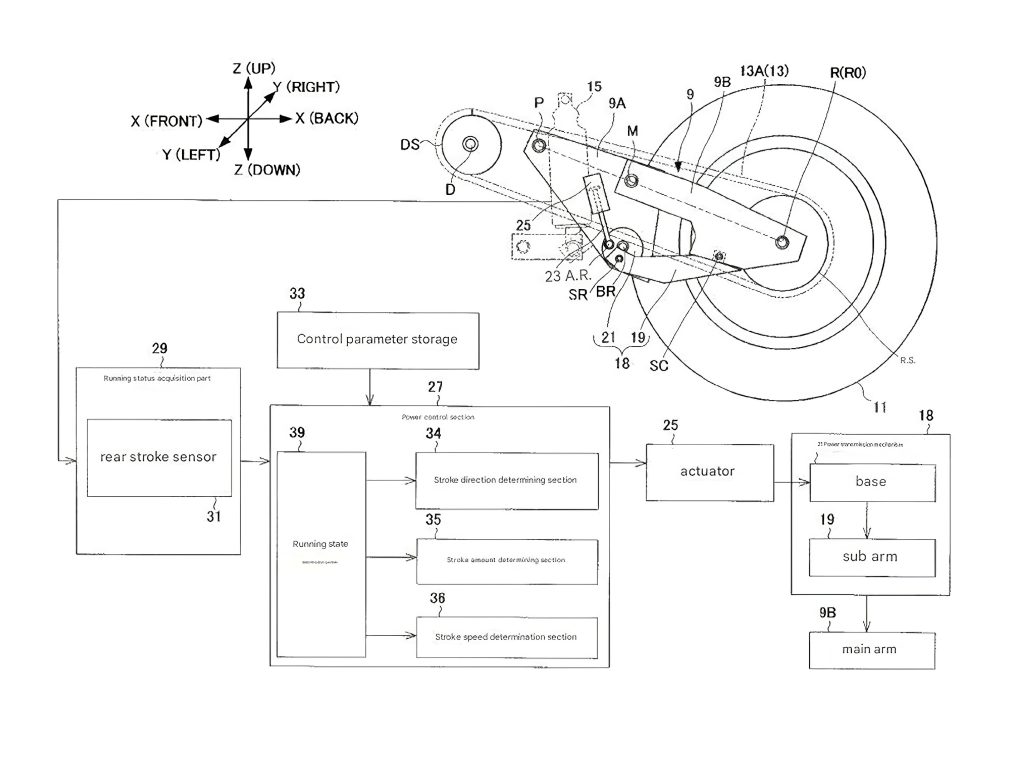

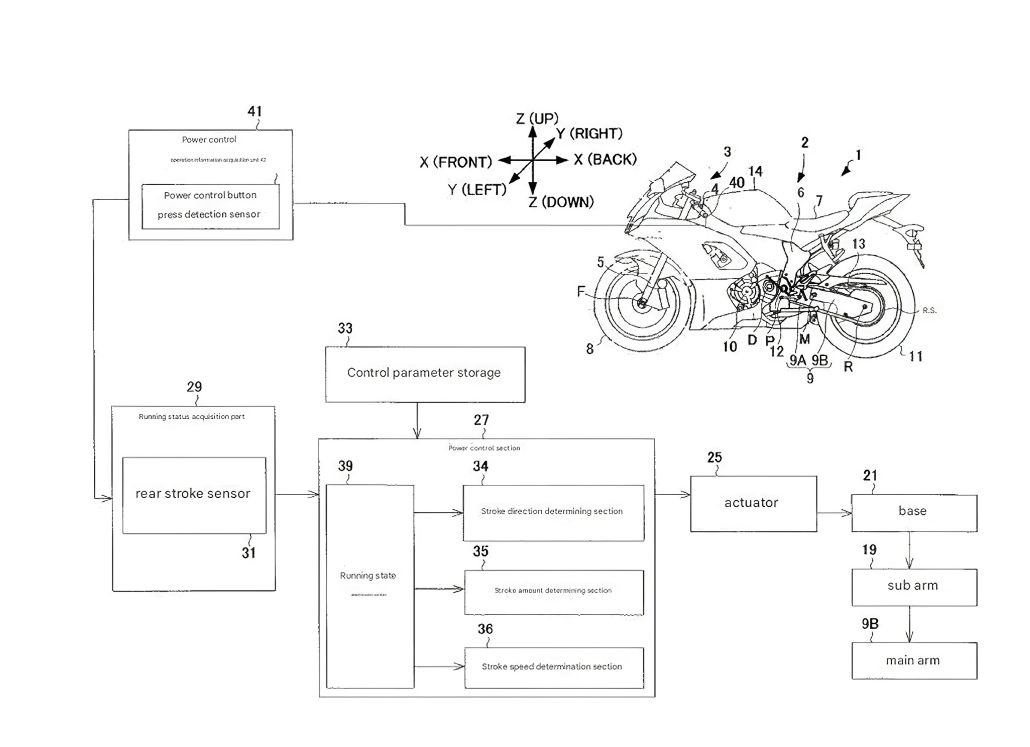

- System is sensor- and actuator-controlled and not purely mechanical

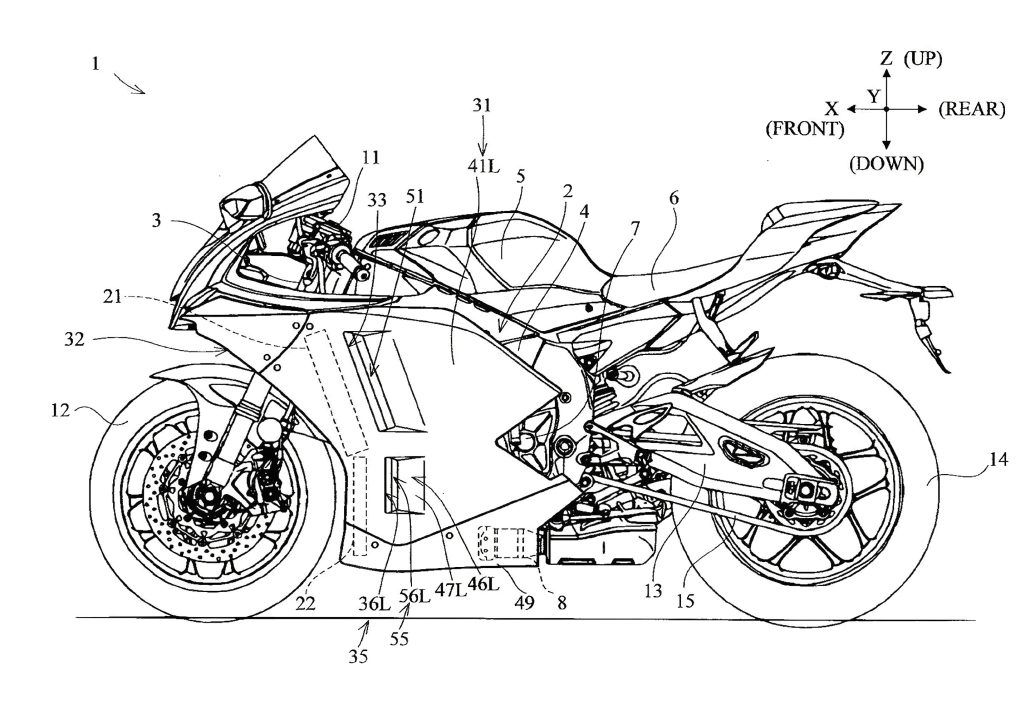

The design of a rear swing arm is one of the most sensitive tasks in chassis design. Shape, stiffness, and targeted flex zones have a significant influence on acceleration, stability, and grip when cornering. These requirements are often contradictory, especially in racing. This is precisely where a new patent from Yamaha comes in, describing a swing arm with variable geometry.

Variable geometry as a logical further development of familiar systems

Variable chassis geometries are nothing new in Grand Prix racing. In MotoGP, ride height devices, which originally evolved from the holeshot systems familiar from motocross, have been used for years. The aim was to lower the motorcycle at the start in order to reduce the tendency of the front wheel to lift and improve acceleration.

These systems were later also used while riding. Especially when accelerating out of corners, the rear could be lowered in a targeted manner to maximize traction. When braking, the rear lifted again, which was intended to enable more precise steering and greater lateral guidance. These solutions worked purely mechanically, as electronic systems are prohibited by the regulations.

Prohibited technology as a source of inspiration

Since 2023, movable front systems have been prohibited while riding. From the 2027 season onwards, rear lowering and holeshot systems will also be completely banned. The Yamaha patent now published shows how this technology could theoretically be further developed if there were no regulatory restrictions.

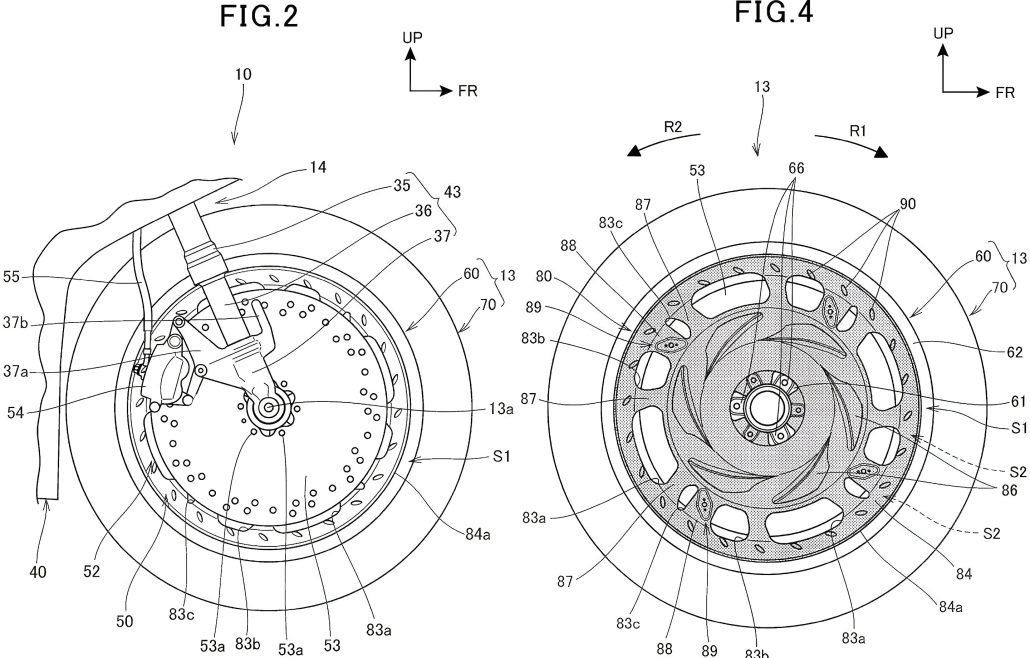

Unlike the solutions known to date, Yamaha does not interfere with the deflection of the shock absorber. Instead, a new approach is being pursued in which the change takes place directly in the swing arm itself.

Design of the swing arm with integrated hydraulic system

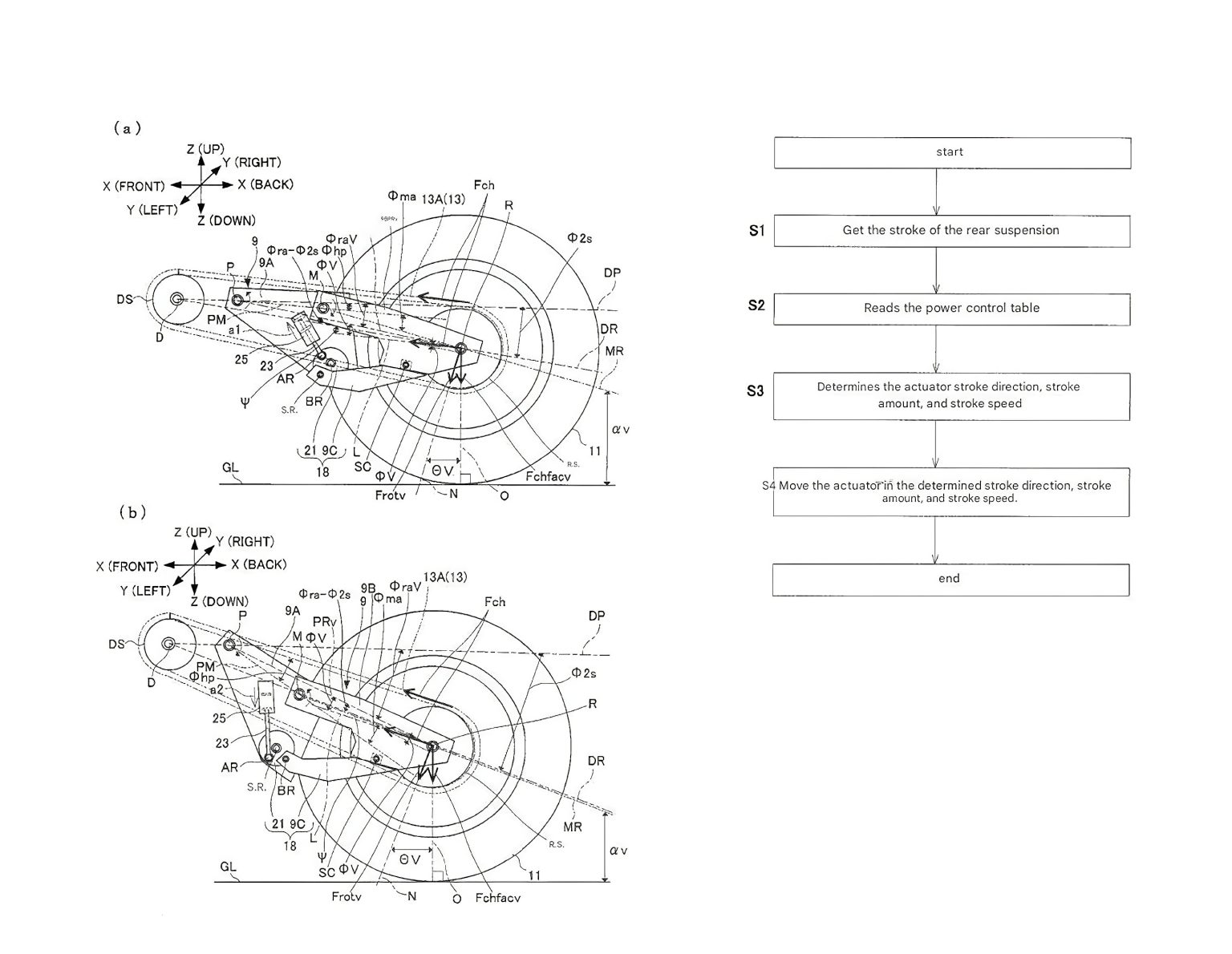

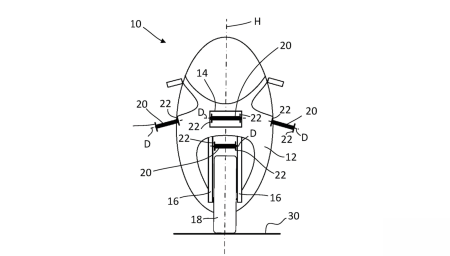

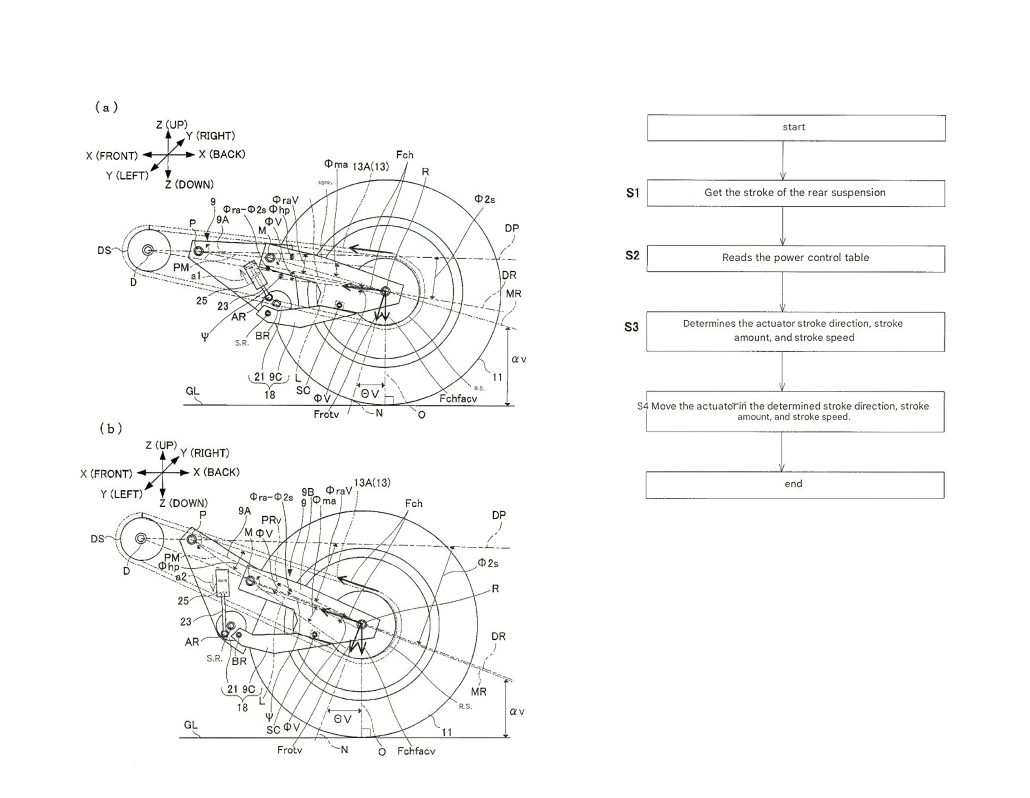

The core of the design is a swing arm with an additional joint in the middle section. The front section is connected to the frame and the suspension strut linkage in the traditional manner. However, the rear section, which guides the rear wheel, can move relative to it.

This movement is controlled by a hydraulic unit built into the swing arm. An eccentric mechanism changes the effective length of a lower strut. Depending on the position, the rear wheel can be raised or lowered without directly affecting the suspension strut. The result is a targeted change in geometry that works independently of the actual suspension travel.

Sensors and actuators instead of mechanics

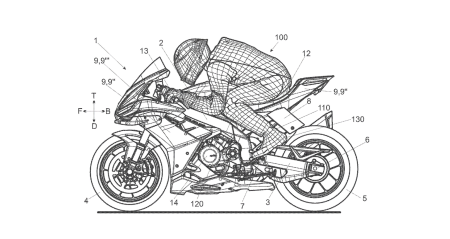

The control approach described in the patent is particularly striking. The system is to be operated by an active actuator that responds to sensor data. Among other things, acceleration, deceleration, and cornering conditions are to be recorded. According to the description, changes in chain tension due to load changes are also incorporated into the control system.

Such an approach would not be permitted under the current MotoGP regulations. This suggests that it is less of a short-term racing project and more of an experimental development tool. The aim is likely to be to better understand the relationships between swing arm flex, geometry, and traction.

High cost with unclear application

The solution described in the patent is extremely complex from a technical standpoint. Additional joints, hydraulics, sensors, and actuators increase weight, installation space, and susceptibility to errors. Direct use in racing or in production motorcycles therefore seems rather unlikely.

Nevertheless, Yamaha is likely to gain valuable insights from the development. Even if the system is never implemented, the data obtained can help to tailor future conventional swing arms more specifically to the conflicting requirements of acceleration and cornering.

What does this mean for me as a motorcyclist?

For the average motorcyclist, the system described above has no direct impact at this stage. It is an experimental patent that is primarily intended for basic research and has not been announced for production motorcycles, nor is it realistic to implement in the short term. Nevertheless, such developments show the direction in which manufacturers such as Yamaha are thinking in the long term. Findings from complex test setups often flow indirectly into later series chassis, for example through optimized swing arm stiffness, better-tuned geometries, or a more balanced interaction between traction and stability. For the rider, this does not mean more technology to operate, but potentially more neutral, more predictable handling of future motorcycles without the need for active intervention.

- ABUS 79270ABUS Bremsscheibenschloss Detecto X-Plus 8008 2.0 Bremsscheibenschloss